TESLA is an emerging Indian engineering company specialised in manufacturing of bricks and block machines. We have a specialised team and facility for manufacturing, installing and managing a full-fledged brick & block production unit anywhere in India. Our facility uses high end computer aided design and manufacturing process, to produce an automatic brick and Block machine, which could be put to use by the customers for effective and efficient brick production. We also have specialised ourselves in setting up complete turnkey manufacturing unit for producing 6 different types of construction blocks for the construction industry.

The business is promoted by young team of engineers having a very rich domain experience in manufacturing and marketing of engineering products for construction industry. Our expertise in the fields of Hydraulics, Pneumatics, metallurgy and electronics reflects in all our product ranges.

The scope of our business not only limits in supplying brick and block machine to our client, we also take up contracts managing the brick production, quality and cost management, machine maintenance, labour management and other related activities to provide a wholesome solution for our clients.

Our service also extends in providing marketing and sales promotion guidance to support them in marketing the brick and block products at their respective regions. TESLA as a team we work with a strong commitment to satisfy our clients with a state of art products and solutions for optimised utilization of resources and maximum profitability for the customers.

Very Limited Manpower to Run the Factory.

Produces up to 60,000 Bricks per day.

What's Your Requierment Our Machine Fulfill It.

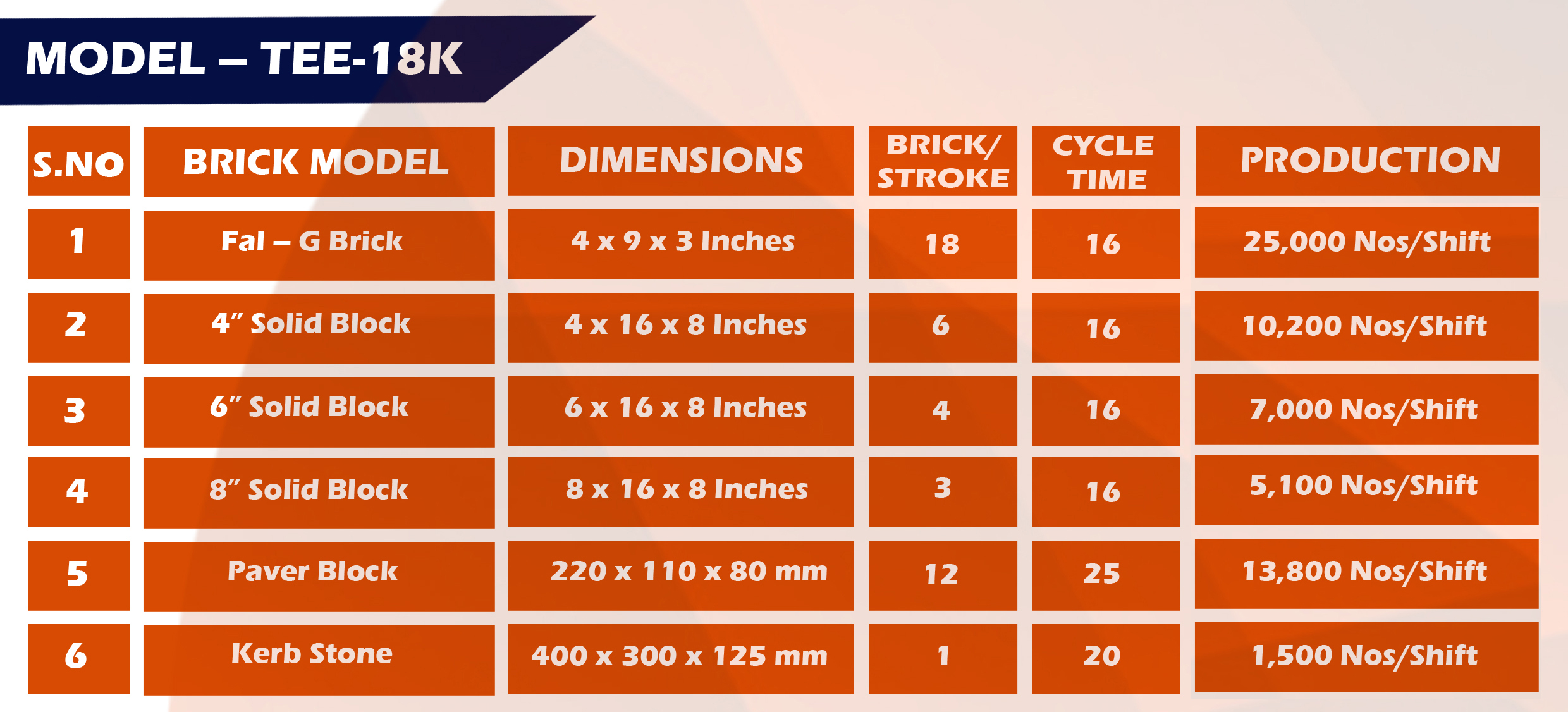

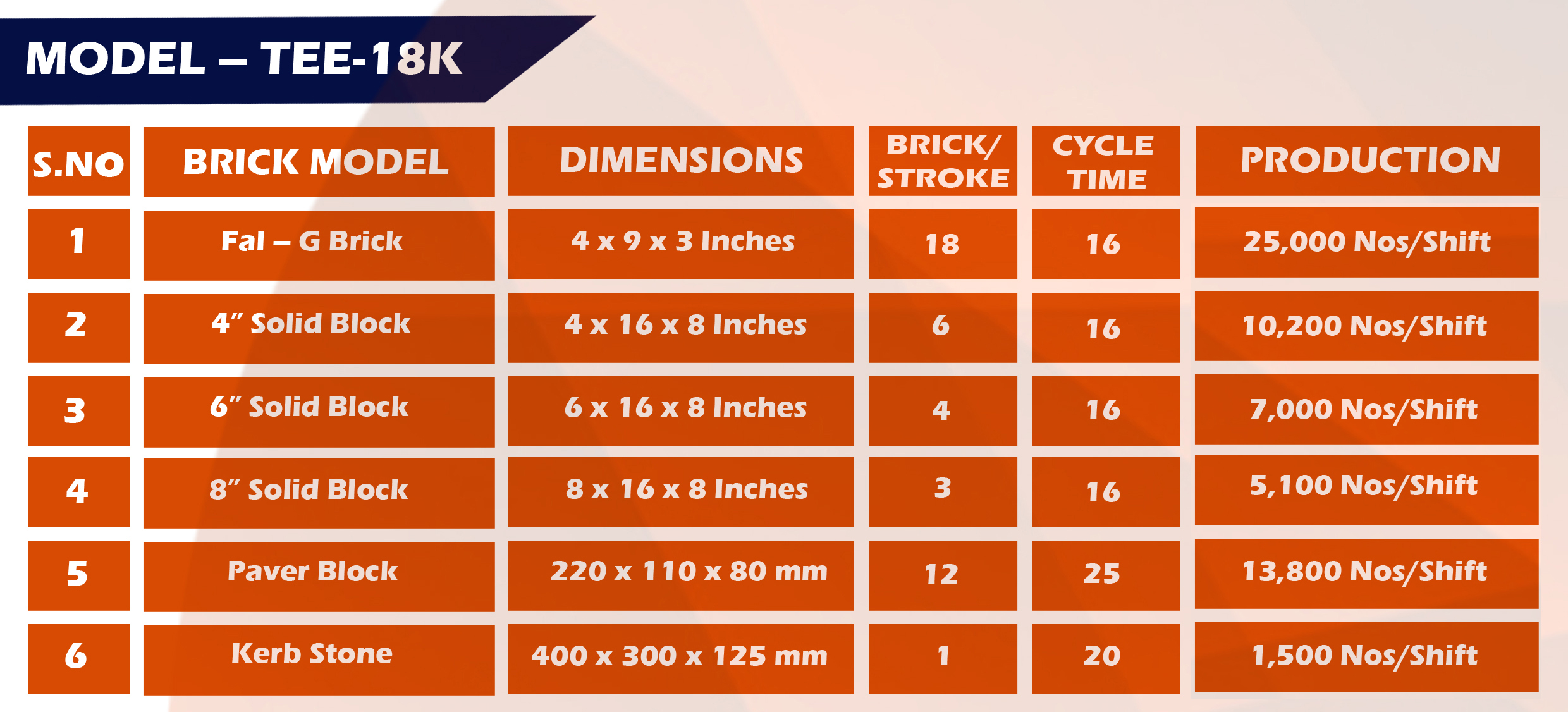

Single Pallet Vibration Machine in TEE-18K features 85 bore cylinders that can deliver up to 9 tons of hydraulic pressure. The cylinders have a defined stroke length of and can compress aggregate and form blocks up to 8 inches in height. The machine also features highly effective vibration system that produces exciting force of 80KN. TEE- 18K can mount over a pallet rail and handling system.

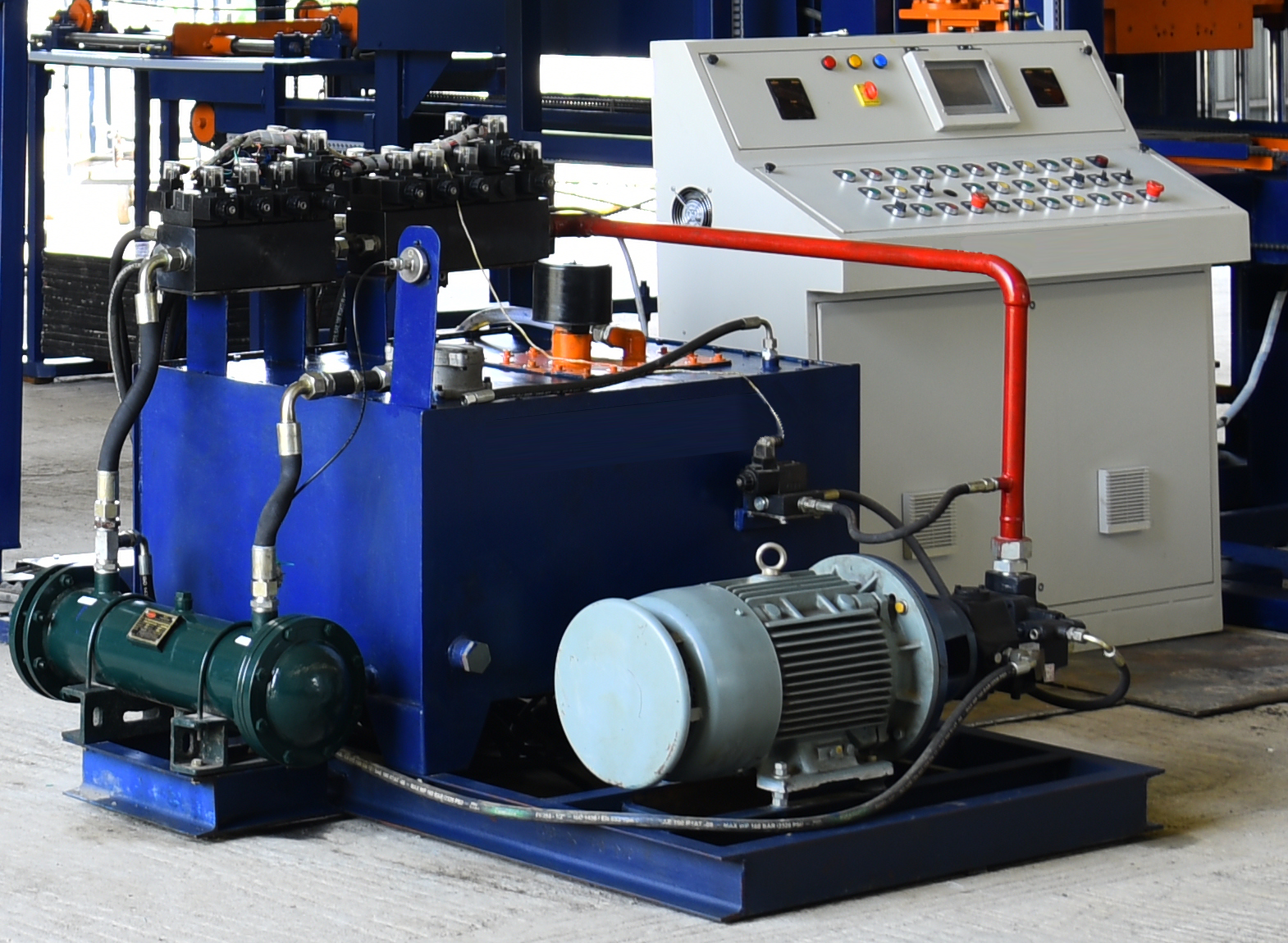

Hydraulic Power pack with 400 liters oil capacity supported by water cooler system and R2 & R9 type houses ensures optimum working temperature for the hydraulic fluids and maintains efficiency even during extended shifts.

Pan Mixer in TEE-18K is fitted with heavy duty rollers and stir arm that effectively breaks down large aggregate and mixes well to prepare a homogenous mixture of raw material. The automatic water management system is controlled by PLC that ensures proper and standard moist level. The capacity of the Pan Mixer is 1000 Kg. The hydraulic hopper system ensures the safety for operator during operation.

Multilayer Vibration Machine in TEE-MVM-18K features 85 bore cylinders that can deliver up to 9 tons of hydraulic pressure. The cylinders have a defined stroke length of and can compress aggregate and form blocks up to 8 inches in height. The machine also features highly effective vibration system that produces exciting force of 80KN. TEE- 18K can mount over a pallet rail and handling system.

Hydraulic Power pack with 400 liters oil capacity supported by water cooler system and R2 & R9 type houses ensures optimum working temperature for the hydraulic fluids and maintains efficiency even during extended shifts.

Pan Mixer in TEE-MVM-18K is fitted with heavy duty rollers and stir arm that effectively breaks down large aggregate and mixes well to prepare a homogenous mixture of raw material. The automatic water management system is controlled by PLC that ensures proper and standard moist level. The capacity of the Pan Mixer is 1000 Kg. The hydraulic hopper system ensures the safety for operator during operation.

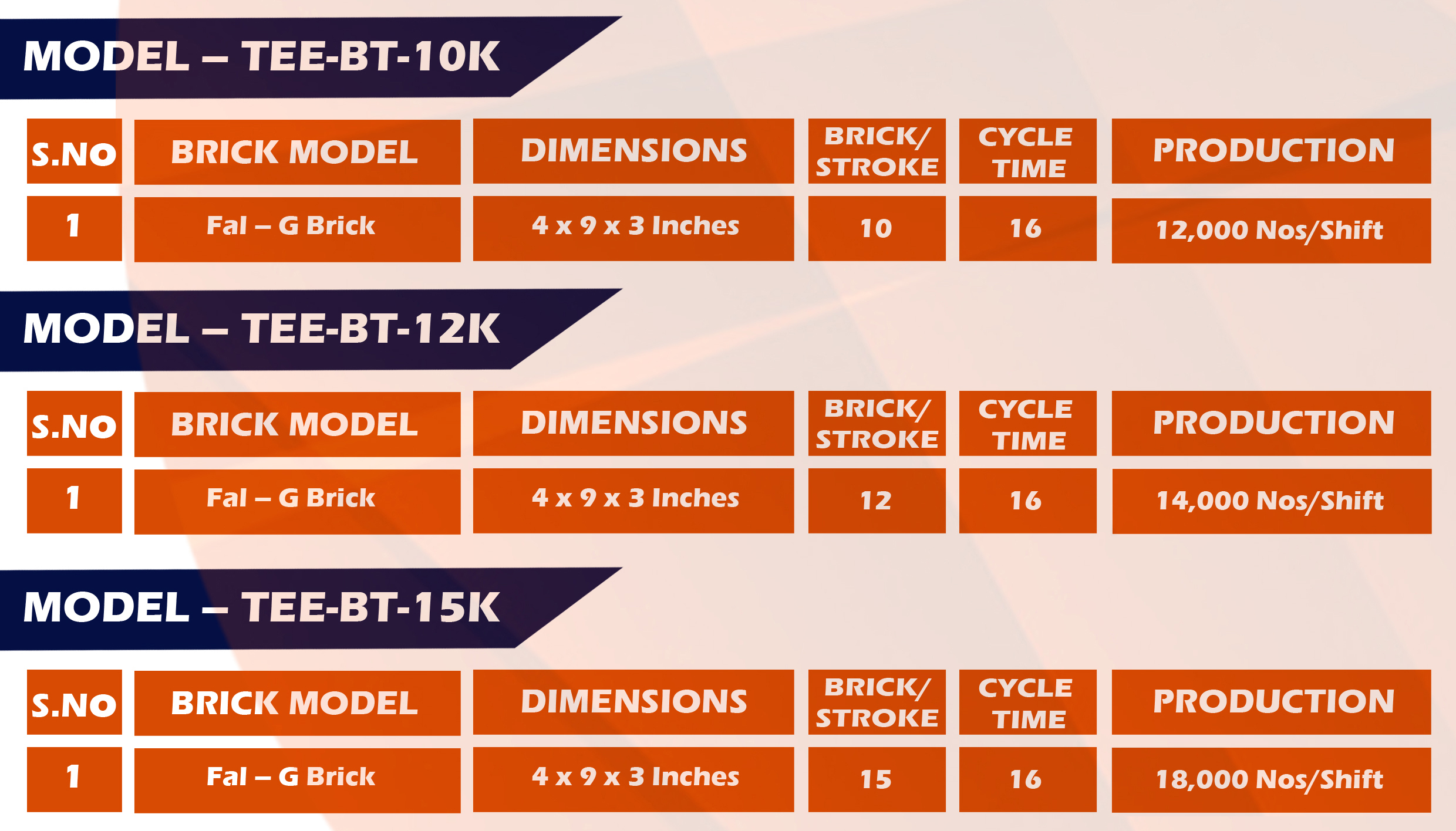

Hydraulic Block Forming Machine in TEE-BT-15K features 350 bore main cylinder, supported by 2 pilot cylinders that can deliver up to 180 tons of hydraulic pressure. The cylinders have a longer stroke length that can compress aggregate and form blocks up to 4 inches in height. TEE-BT-15K can mounted over a belt conveyer system or over a pallet rail and handling system.

Hydraulic Power pack with 400 liters oil capacity supported by water cooler system and R2 & R9 type houses ensures optimum working temperature for the hydraulic fluids and maintains efficiency even during extended shifts.

Pan Mixer in TEE-BT-15K is fitted with heavy duty rollers and stir arm that effectively breaks down large aggregate and mixes well to prepare a homogenous mixture of raw material. The automatic water management system is controlled by PLC that ensures proper and standard moist level. The capacity of the Pan Mixer is 1000 Kg. The hydraulic hopper system ensures the safety for operator during operation.

Hydraulic Block Forming Machine in TEE-A1-18K features 350 bore main cylinder, supported by 2 pilot cylinders that can deliver up to 180 tons of hydraulic pressure. The cylinders have a longer stroke length that can compress aggregate and form blocks up to 8 inches in height. The machine also features highly effective vibration system that produces exciting force of 100KN. This machine can mount over a pallet rail and handling system.

Hydraulic Power pack with 400 liters oil capacity supported by water cooler system and R2 & R9 type houses ensures optimum working temperature for the hydraulic fluids and maintains efficiency even during extended shifts.

Pan Mixer in TEE-A1-18K is fitted with heavy duty rollers and stir arm that effectively breaks down large aggregate and mixes well to prepare a homogenous mixture of raw material. The automatic water management system is controlled by PLC that ensures proper and standard moist level. The capacity of the Pan Mixer is 1000 Kg. The hydraulic hopper system ensures the safety for operator during operation.

Bin Feeders (Fly Ash,Quarry Dust,Cement) with Structural Supports, vibrating motor & 3 side covering Plates to suit load the materials by Tractor Loader.

Bin Discharge outlets with Pneumatic Air Cylinder with Auto Discharge System duly programmed by PLC based Control Panel System.

Air Compressor with Electric motor, required Pipe line, safety valve, filter & Accessories.

Gathering Belt Weigh Conveyor System comprises of Top Collection Hopper, with Load cell based Belt Weighing arrangement, PLC based Control Panel with External setting of various recipes & varieties of Ingredients.

Raw Material Inclined Transfer Conveyor System – (App. Length 8 - 10 Mtrs depend upon Layout of Site)

Cement storage & Feeding system with drive Cement feeding through Screw Conveyor, WAM Make 5 HP Geared Motor and feeding system 500 kg/ hr. Cement weigh scale with hopper PLC controlled load cell based weight batching system to batch and discharge upto 500 kg/hr. cement to the mixer Automatic Water feeding system with timer based Solenoid operated valve and 1HP submerged Water Pump and Water Feeding system for Pan mixer with required Pipeline and Pipe connection for Water circulation of Heat exchanger. (Underground RCC Water Tank will be arranged by client)

Electrical Control Panel comprises of Standard make Contactors, Relay, Main Switch, ON / OFF Switch, Ampere Meter and Standard make PLC and HMI Display.

Bins for Fly Ash, Q.Dust, Cement with Structural Supports, vibrating motor & 3 side covering Plates to suit load the materials by Tractor Loader.

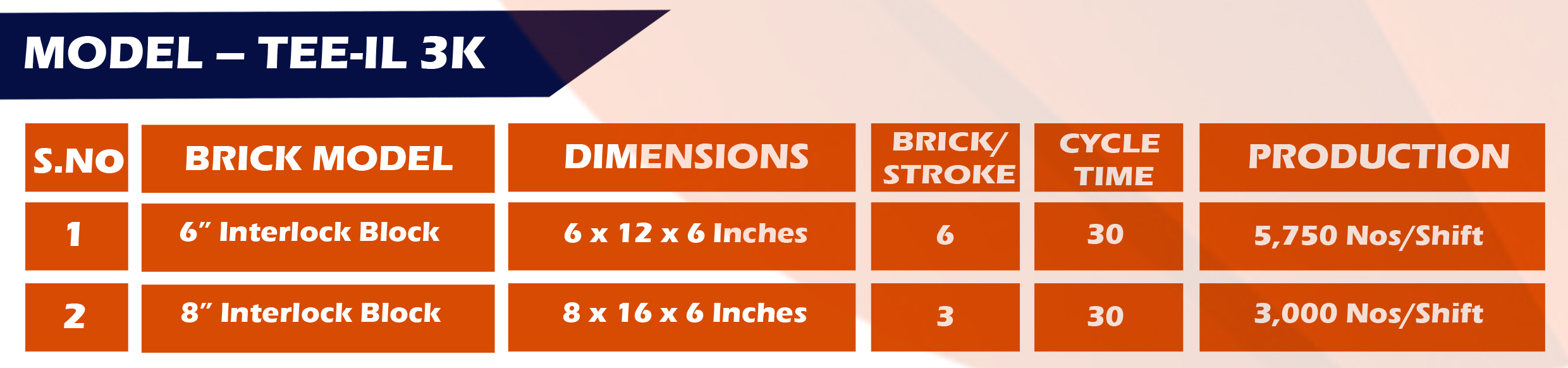

Interlocking Brick Machine-TEE-IL 3K features 100 bore main cylinder can deliver up to 10 tons of hydraulic pressure. The cylinders have a longer stroke length that can compress aggregate and form blocks up to 8 inches in height. TEE-IL-3K can mounted over a pallet rail and handling system.

Hydraulic Power pack with 20 liters oil capacity supported by water cooler system and R2 & R9 type houses ensures optimum working temperature for the hydraulic fluids and maintains efficiency even during extended shifts.

Pan Mixer in TEE-IL-3K is fitted with heavy duty rollers and stir arm that effectively breaks down large aggregate and mixes well to prepare a homogenous mixture of raw material. The capacity of the Pan Mixer is 200 Kg.

+91-8124464816

+91-8300362633

Sales Team |

|

sales@teebm.co.in |

+91-8148493648 |

Mr.Pius Nirooban B.Tech.,

Mr.Rathanam MA.,LLB.,